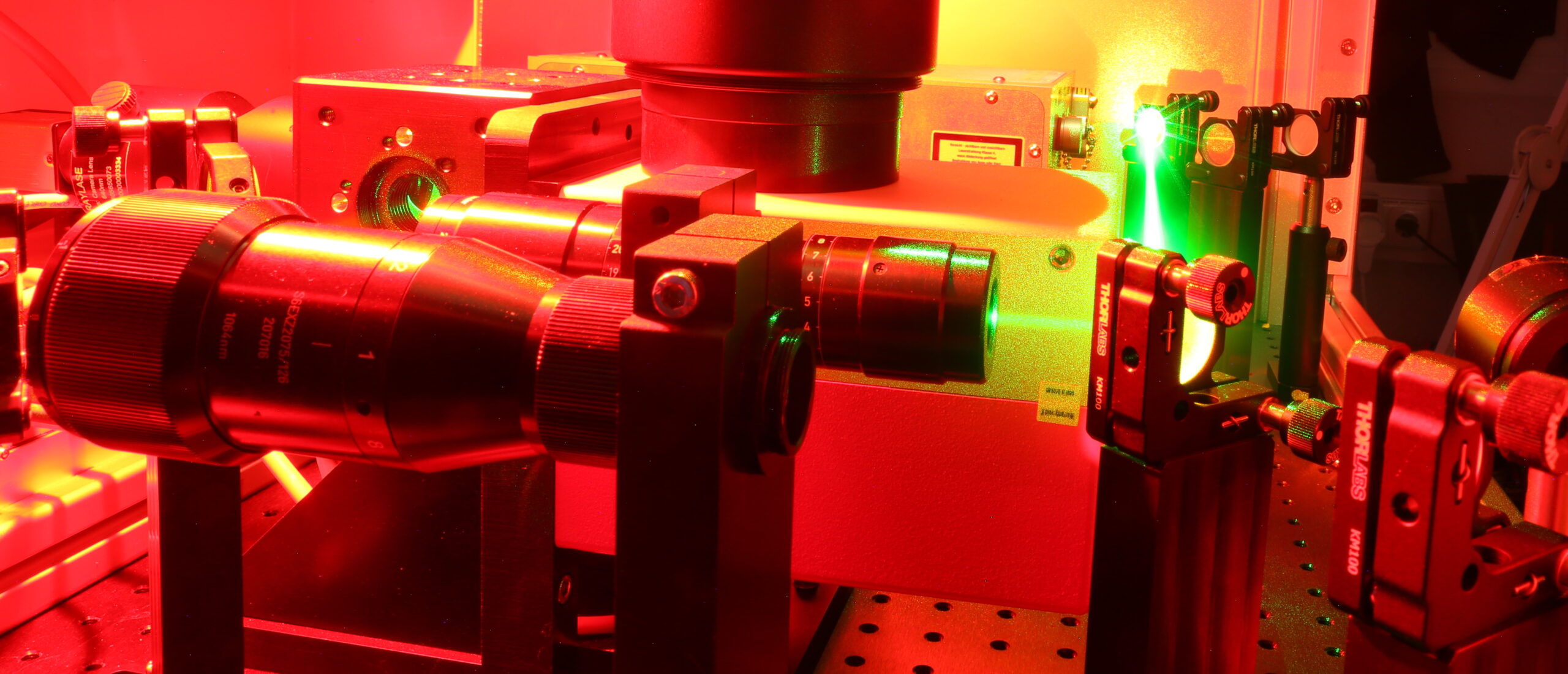

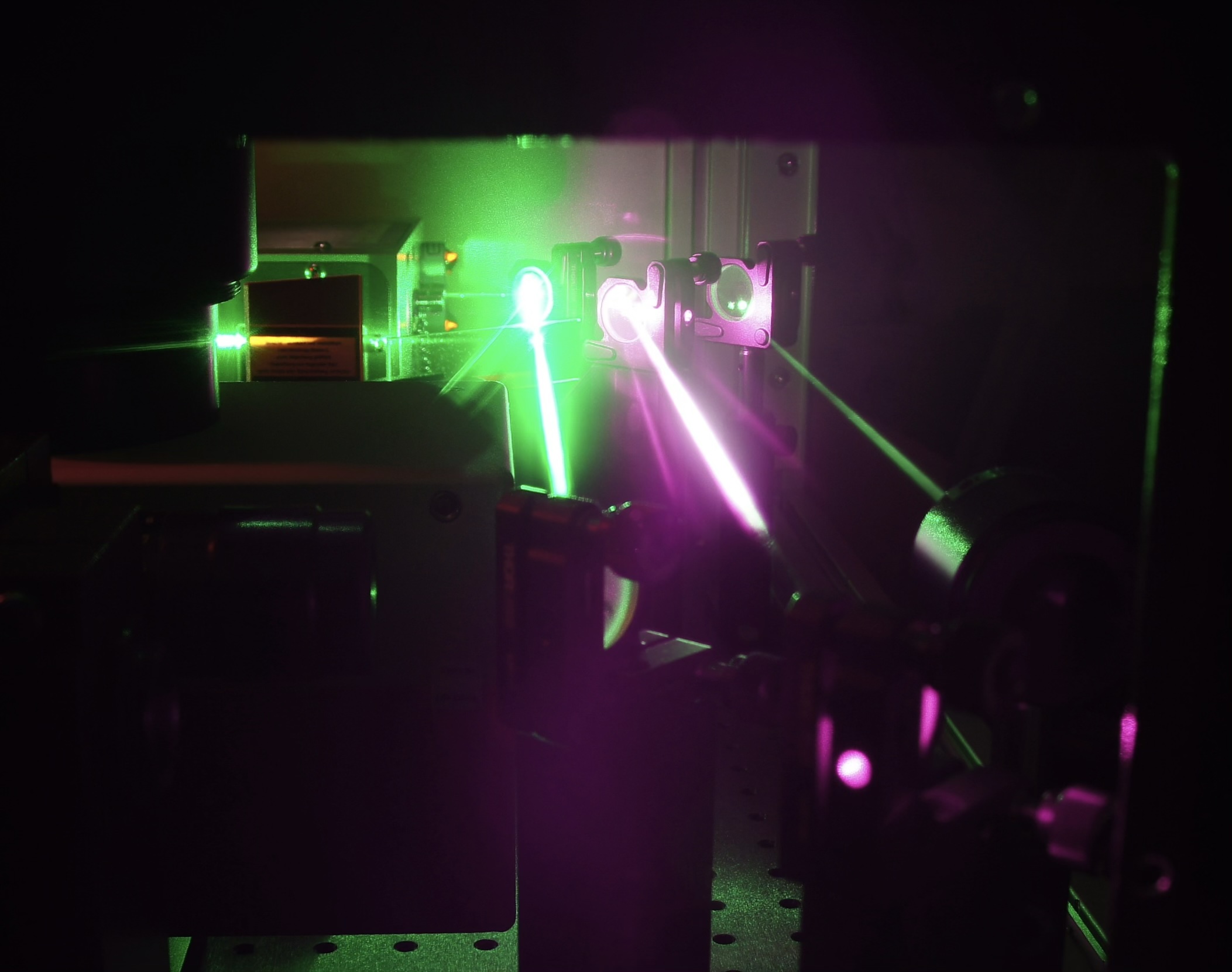

Multi-wavelength laser systems

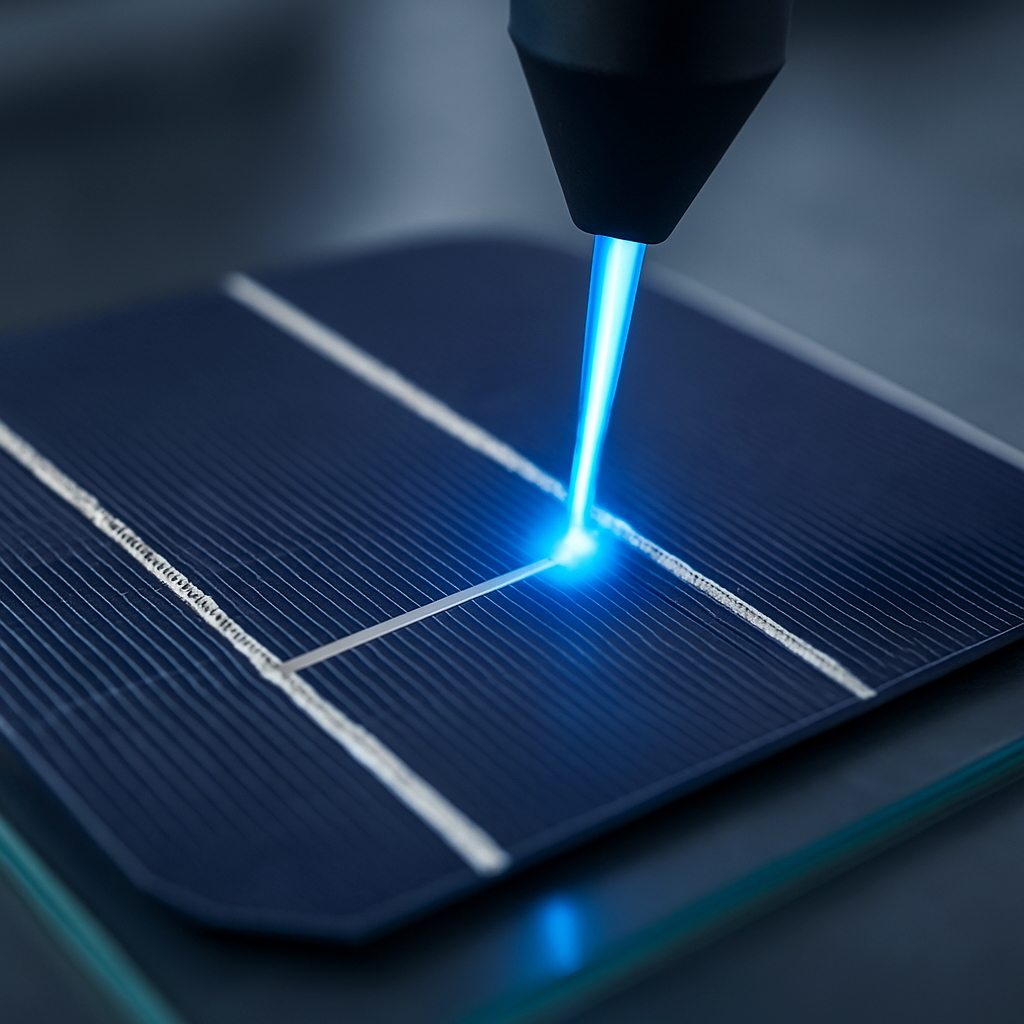

Versatile Multi-Wavelength Laser Systems for Selective Material Processing

We provide advanced laser systems that combine multiple wavelengths—1064 nm, 532 nm, and 355 nm—in a single, integrated solution. This enables precise, material-selective layer processing within one setup.

For example:

532 nm effectively removes semiconductor materials from transparent electrodes.

355 nm can ablate transparent electrodes from glass substrates.

1064 nm allows for the removal of metal electrodes from semiconductor layers.

The desired wavelength can be selected via computer control, allowing flexible, automated processing of different material layers in a single workflow.

R+D laser systems for photovoltaic research

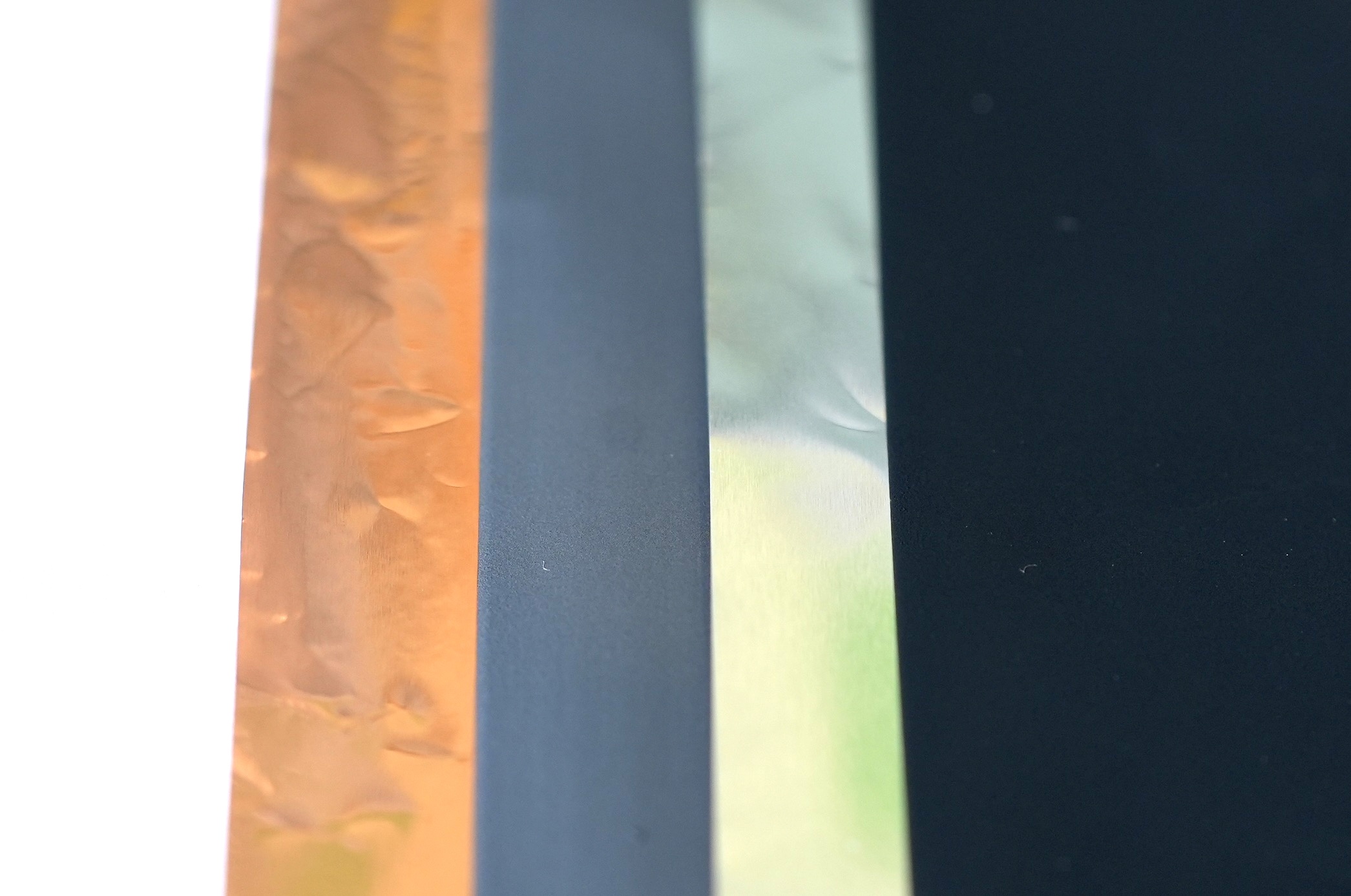

Different laser enclosures

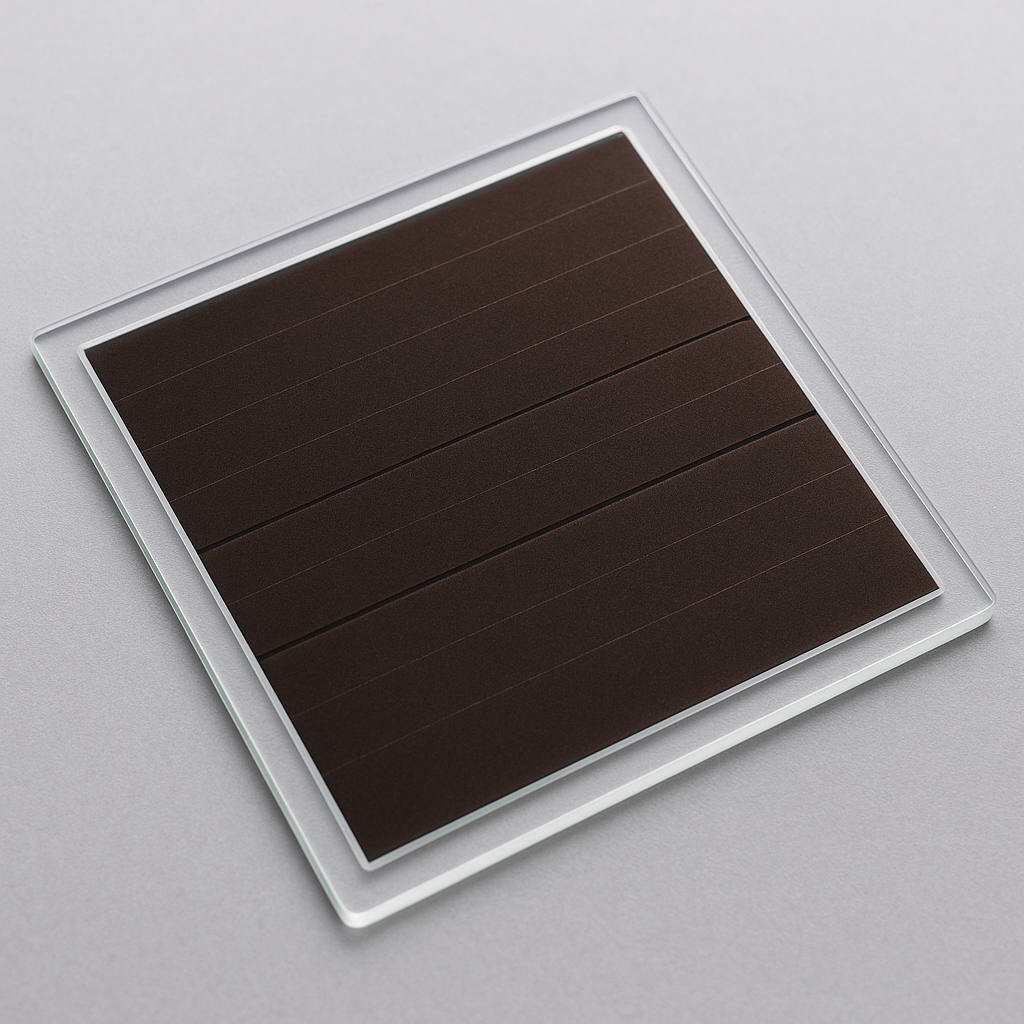

Laser scriber for perovskite solar cells and solar modules

For thin-film solar modules and tandem cells

Available as mobile laser system for air

And available as laser system for glove box

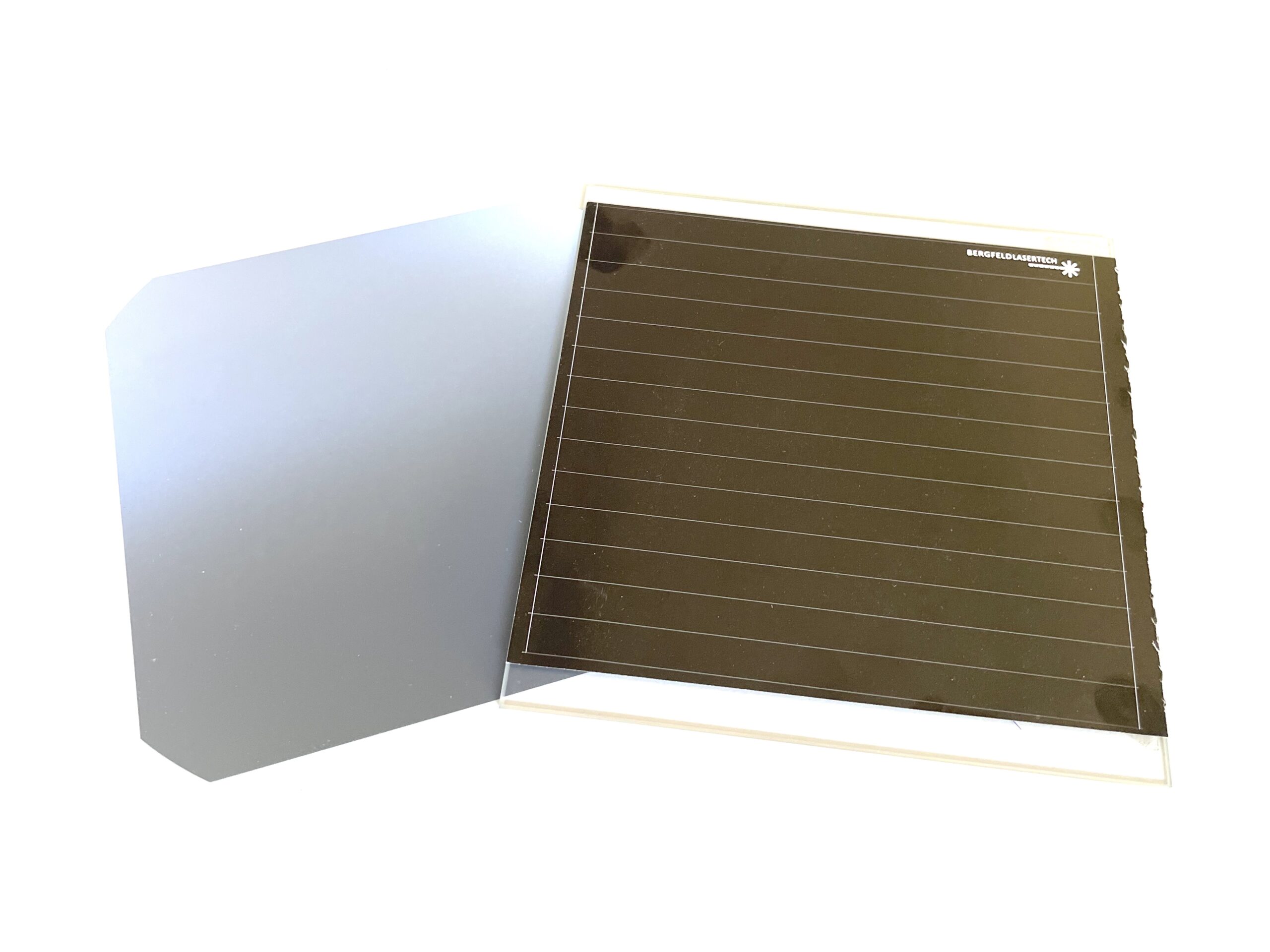

Laser processes for battery electrodes with multiple wavelength laser system

Laser Processes for Battery Electrodes with multiple wavelength laser system

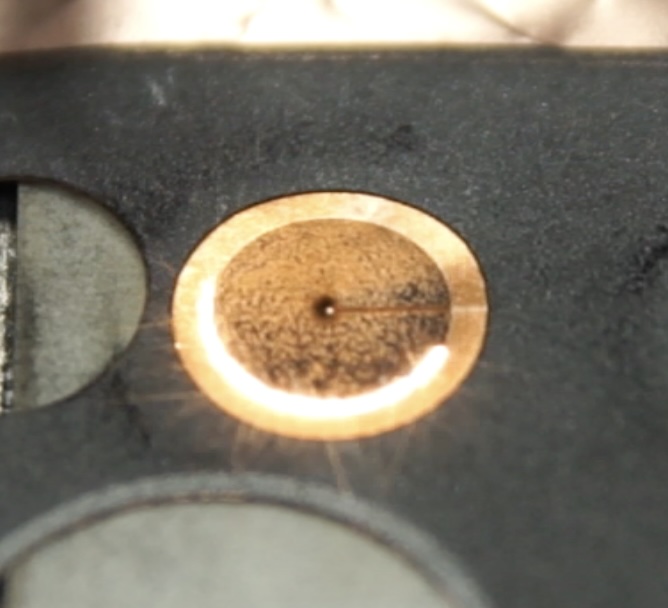

- 1064 nm decoating of battery electrodes from active material without damaging the copper or aluminum foil

- 532 nm cutting of aluminum and copper, de oxidizing and activation of metal foils

- 355 nm precise cutting of metal foils, opening of battery packs without mechanical stress

Our femto, pico and nanosecond laser portfolio

Applications (examples)

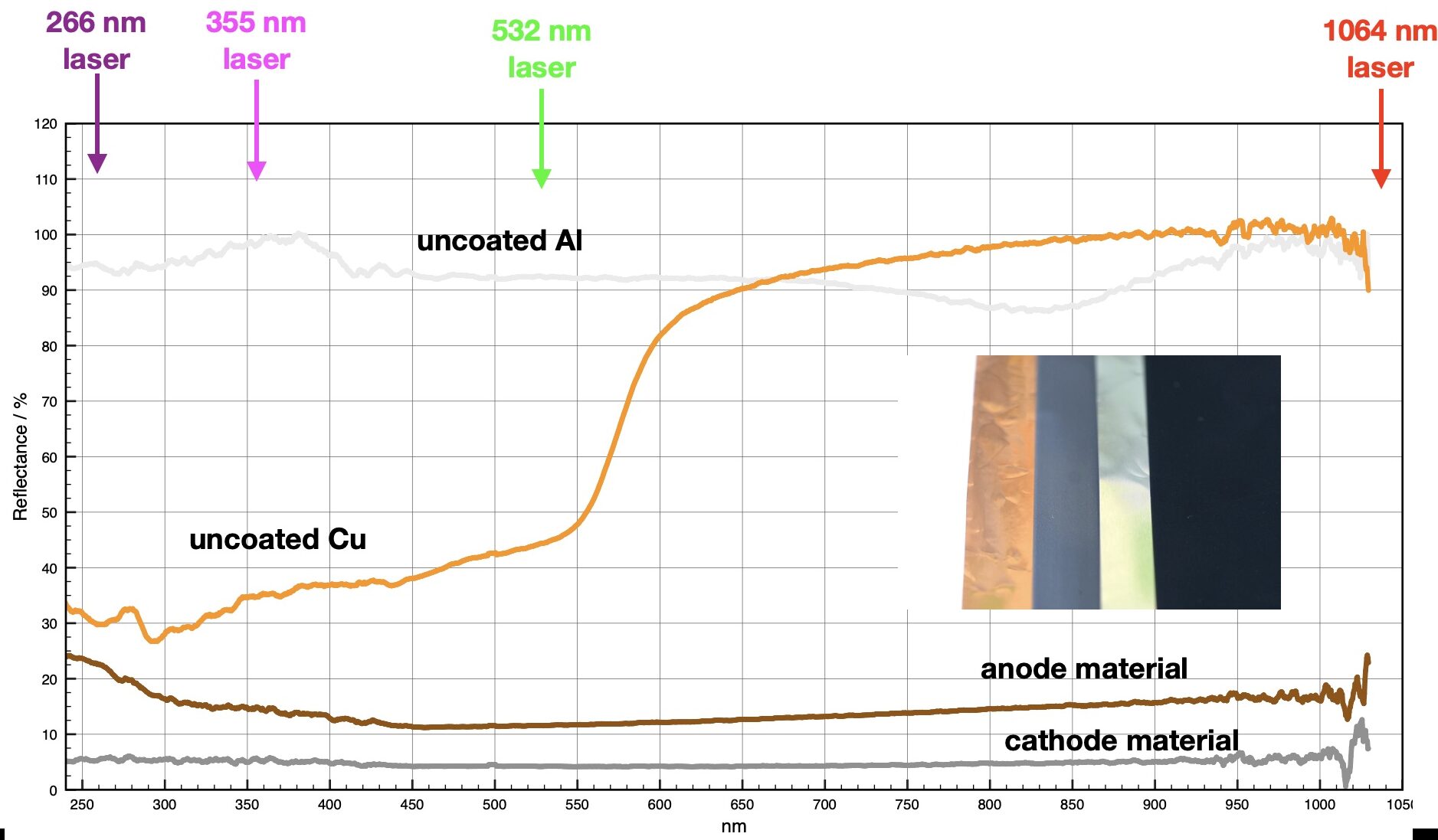

Laser Processes for Battery Electrodes with multiple wavelength laser system

- 1064 nm decoating of battery electrodes from active material without damaging the copper or aluminum foil

- 532 nm cutting of aluminum and copper, de oxidizing and activation of metal foils

- 355 nm precise cutting of metal foils, opening of battery packs without mechanical stress