Laser processes for perovskite solar cells (PSC)

We are offering different processes. Since our laser systems have multiple laser wavelength many processes can be performed in one system. For example:

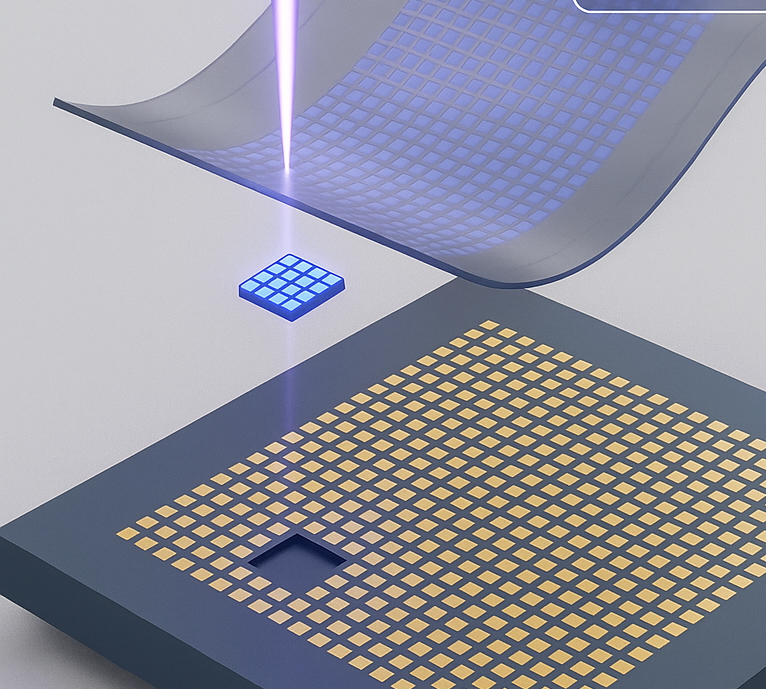

- Laser interconnection of solar cells to solar modules via P1, P2 and P3 laser scribing

- P4 laser scribing to avoid to high currents in areas of the module

- Laser edge deletion (LED) for isolation the active area from the environment and for aciving a reliable and electrically insulated area for encapsulation

- Laser contact cleaning (LCC) for contacting the modules via bus bars.

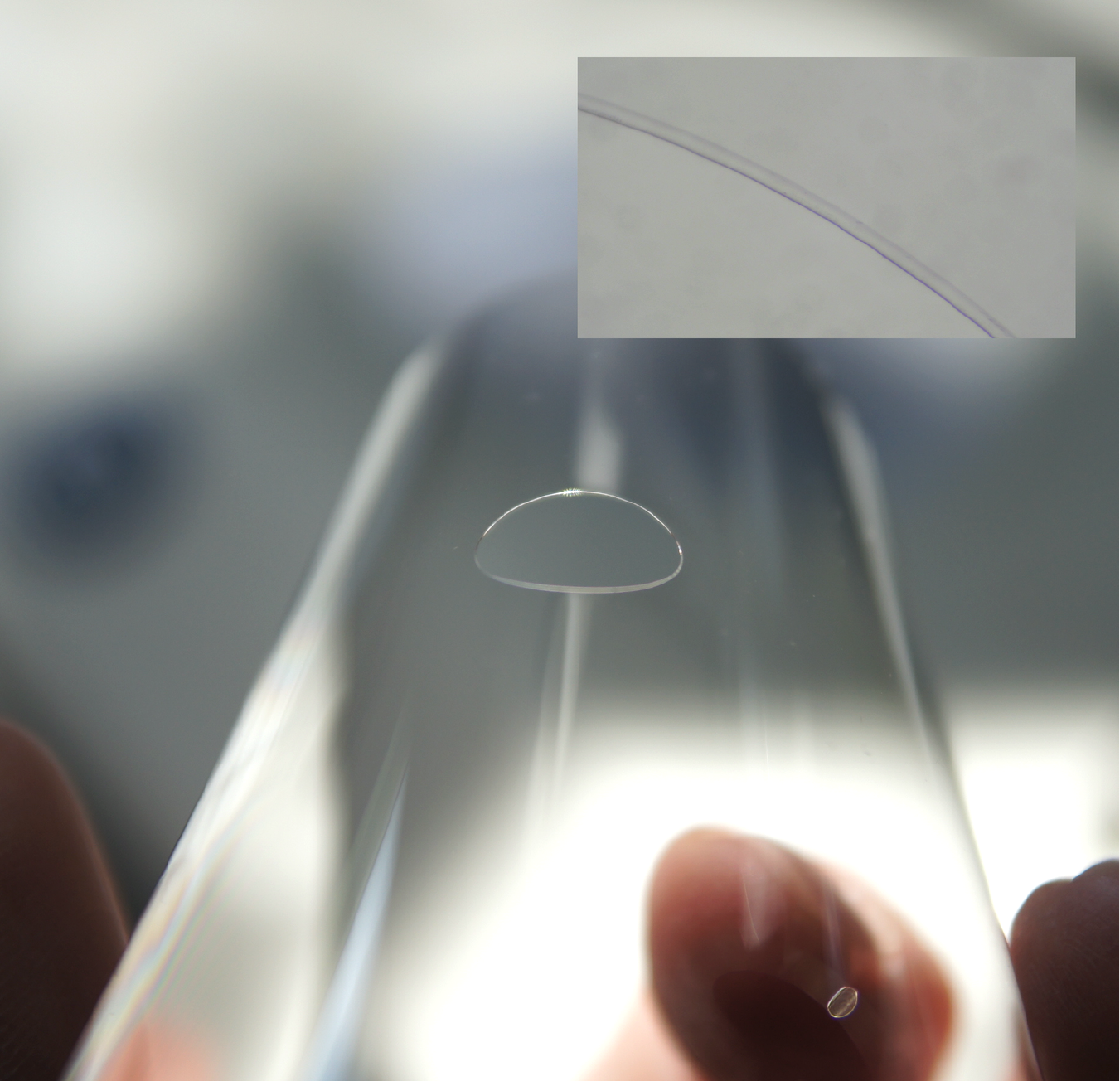

Together with a research institute we are working on encapsulation of glass-glass modules via laser glass-glass welding.

We also offer photoluminescence (PL) and electroluminescence (EL) imaging in our GLOBOLAS and PEROLAS systems. For the PL and EL imaging the internal camera for positioning is used. For PL we offer top-hat laser diodes in different wavelength.

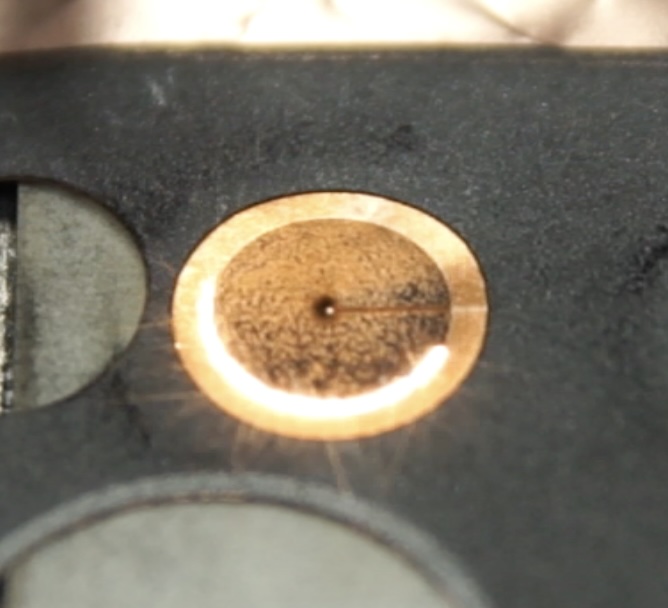

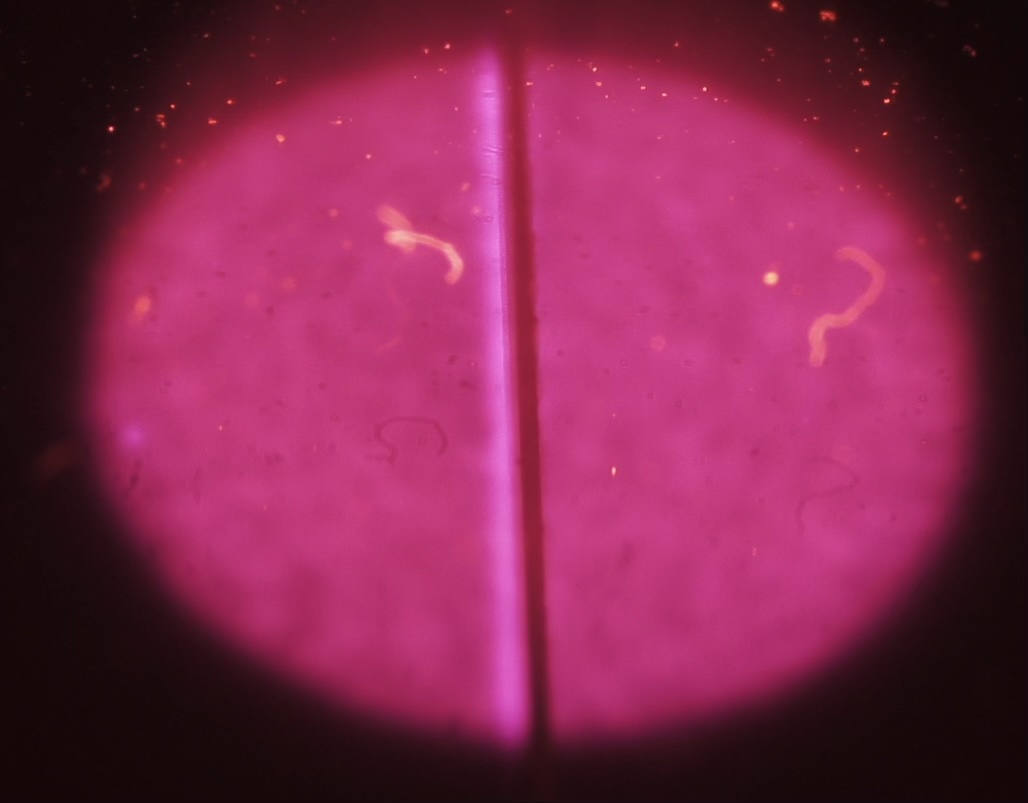

Photoluminescence imaging (PL)

PL image of a laser scribe in CIGS. The sample was illuminated with our top hat 532 nm diode laser. We can integrate the PL imaging hardware in our PEROLAS and GLOBOLAS laser systems. The camera is sensitive in the range of 805, 0r 800 or 750 nm depending on the optical filter setup. We also offer top hat laser diodes with 950 nm, 808 nm, 650 nm and 450 nm additionaly to the 520 nm

Semi transparent solar modules for building integratet photovoltaic (BIPV)

In our PEROLAS and GLOBOLAS laser systems we use different laser sources to erase the semi conductor and back contact via laser without short cutting the devices. It is also possible to erase the front contact in the same step.

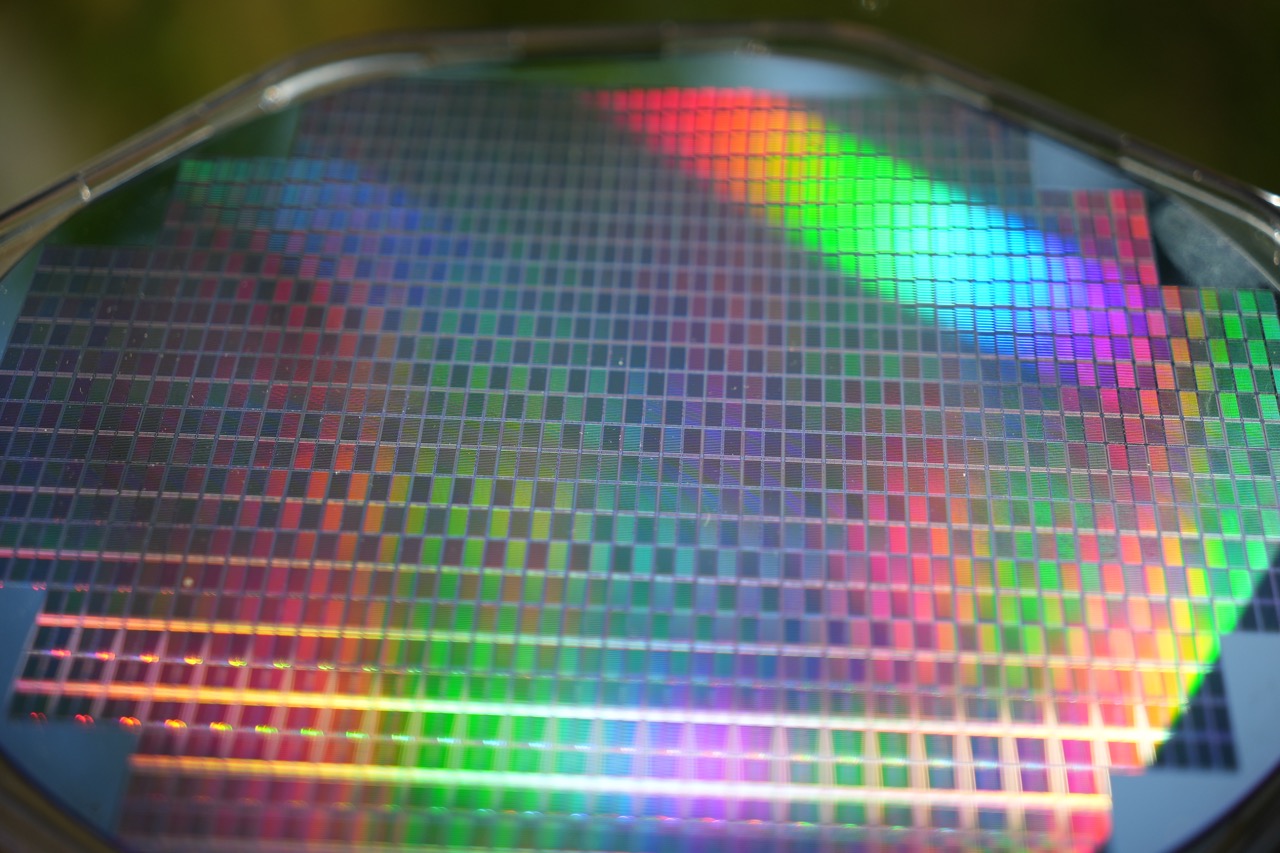

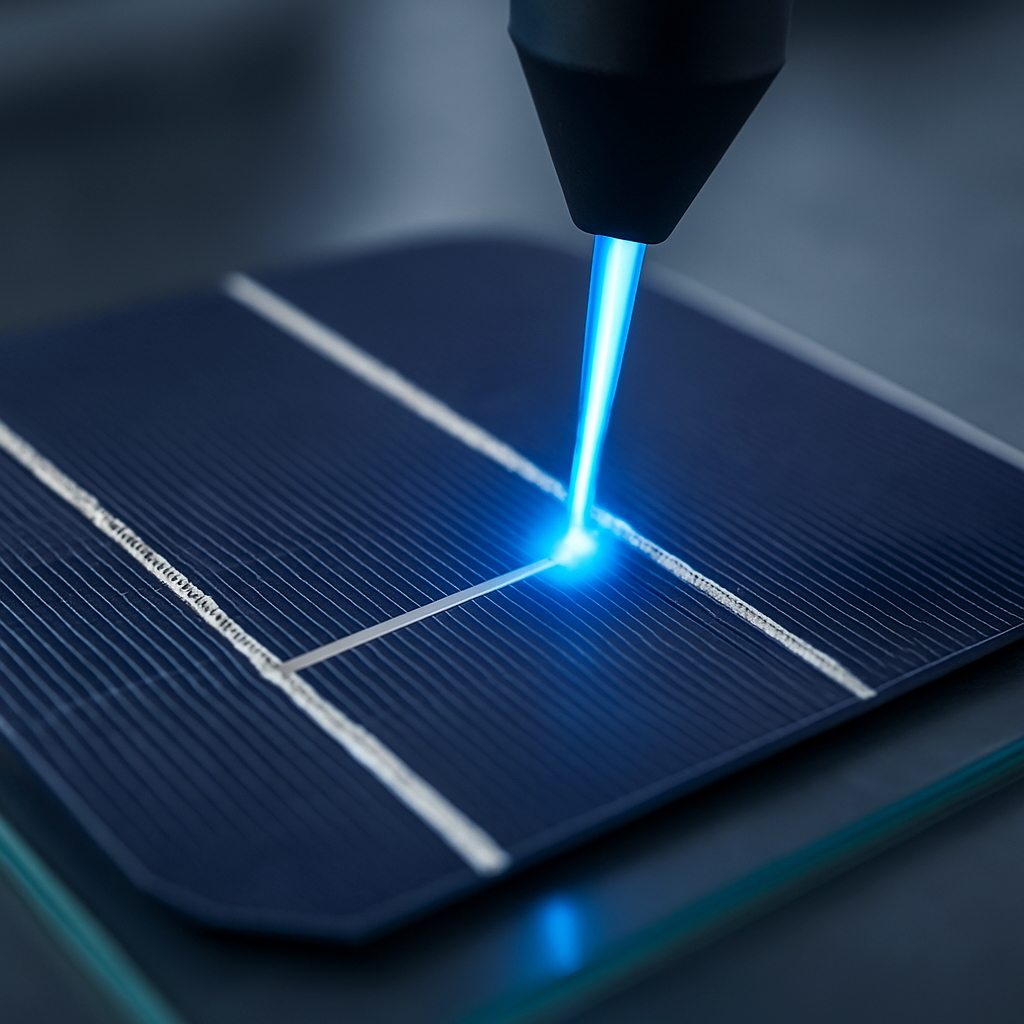

Laser processes for wafer based crystalline silicon solar cells (c-Si)

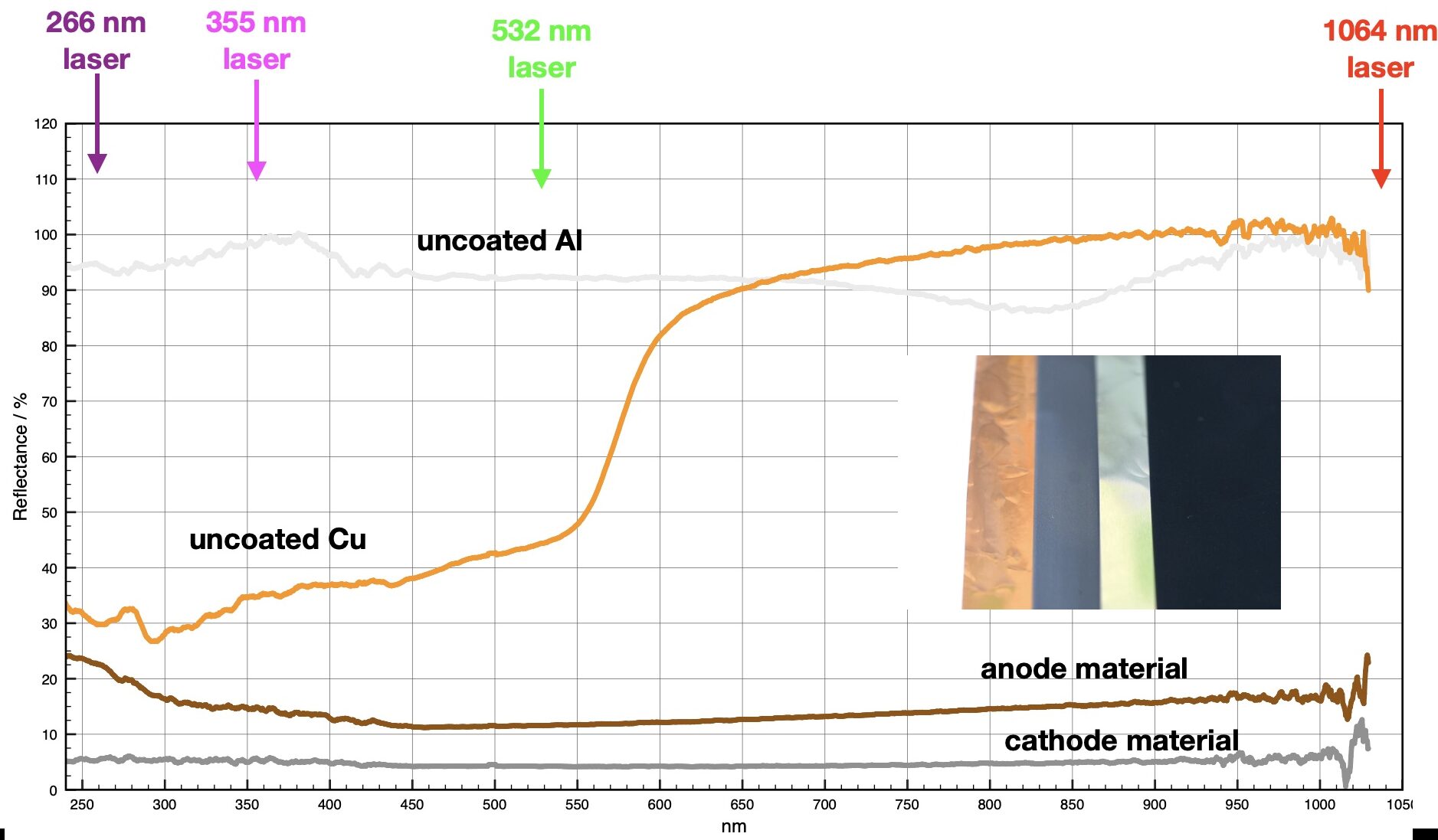

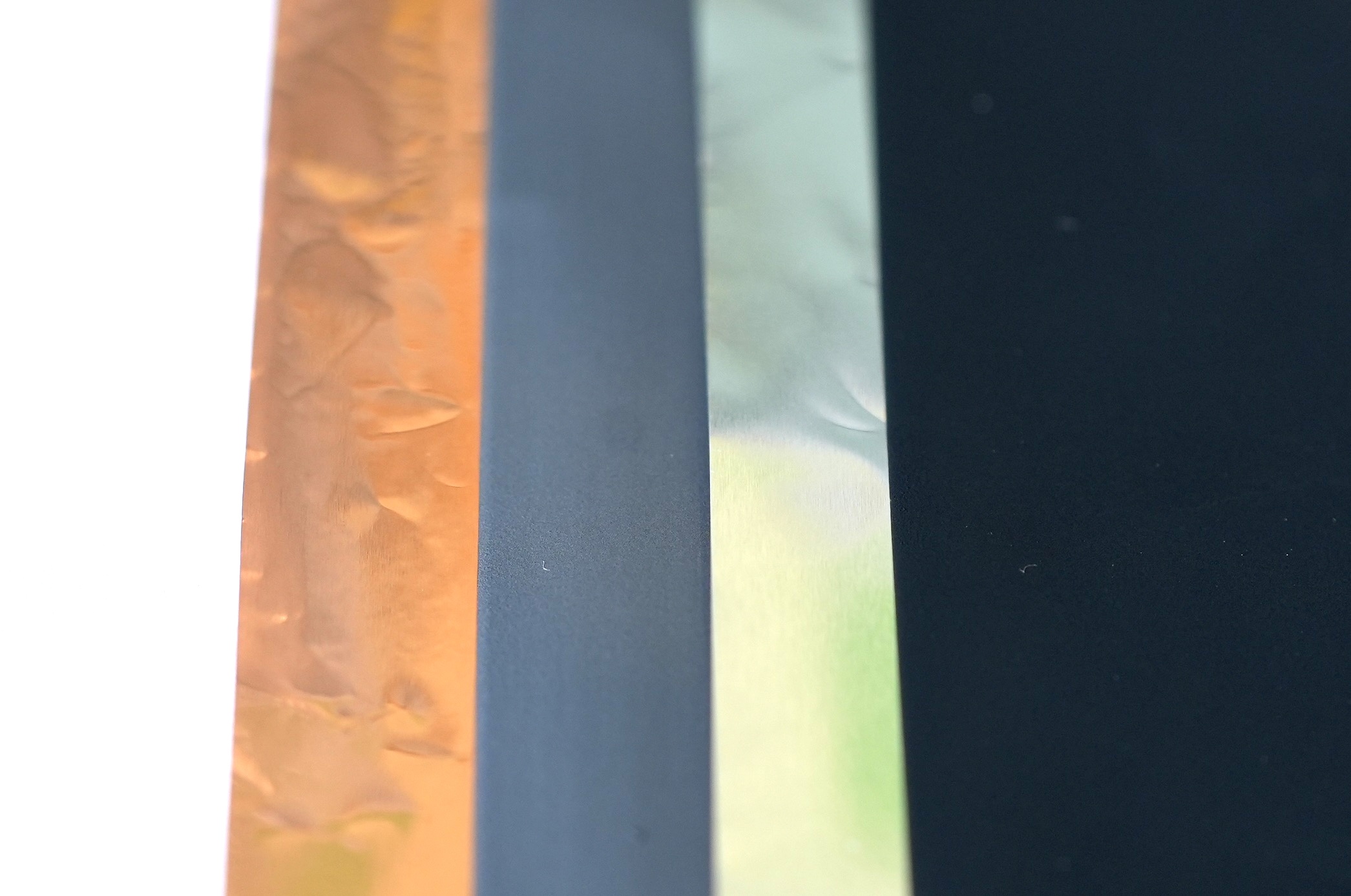

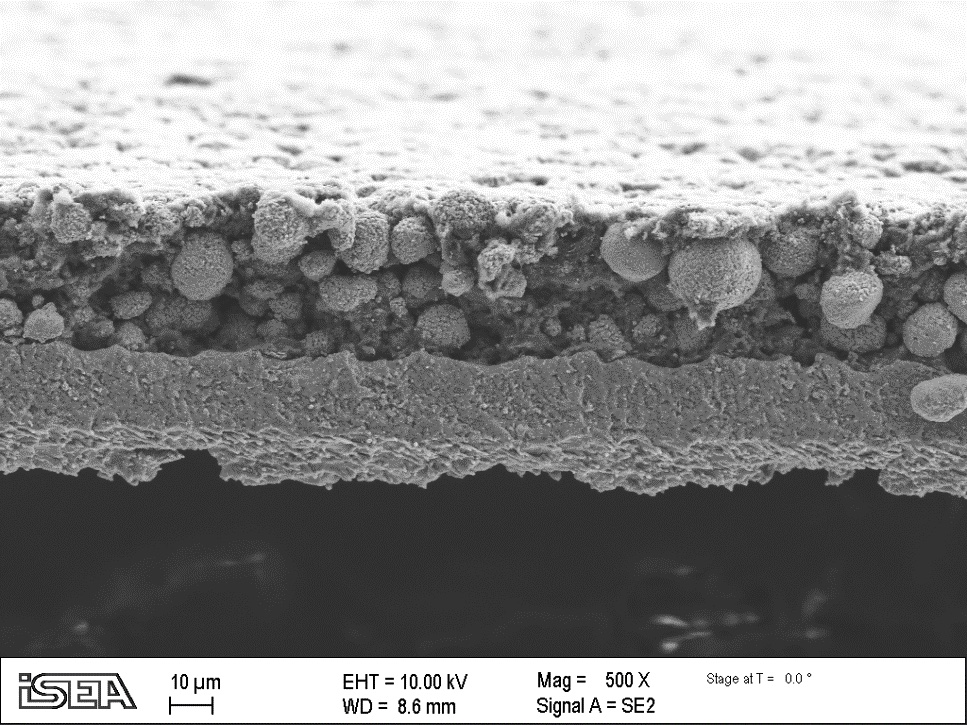

Laser processes for battery electrodes with multiple wavelength laser system

Laser Processes for Battery Electrodes with multiple wavelength laser system

- 1064 nm decoating of battery electrodes from active material without damaging the copper or aluminum foil

- 532 nm cutting of aluminum and copper, de oxidizing and activation of metal foils

- 355 nm precise cutting of metal foils, opening of battery packs without mechanical stress