Laser system for femtosecond laser processing of glass

Available as mobile laser system for air

And available as laser system for glove box

Bulk modification & 3D laser writing in glass

Bulk modification using femtosecond laser pulses enables localized, non-linear energy deposition inside transparent materials without affecting the surface.

This process is commonly used for 3D laser writing, allowing the fabrication of buried waveguides, photonic circuits and refractive index patterns in glass.

The interaction is highly confined to the focal volume, enabling true three-dimensional structuring with micrometer precision.

Refractive index modification (waveguide writing)

Refractive index modification (RIM) is achieved by tightly focusing ultrashort laser pulses inside glass, inducing permanent, localized changes in the material structure.

This technique is widely used for waveguide writing, integrated photonics and optical routing in transparent substrates.

The achievable index contrast and mode profile depend on laser parameters, focusing conditions and glass composition.

Selective Laser Etching (SLE)

Selective Laser Etching (SLE) combines femtosecond laser modification of glass with subsequent chemical etching to create complex three-dimensional microstructures.

Laser-modified regions exhibit significantly increased etch rates compared to unmodified glass, enabling high-aspect-ratio structures.

SLE is particularly suited for microfluidics, micromechanics and glass-based microdevices that cannot be realized by planar fabrication techniques.

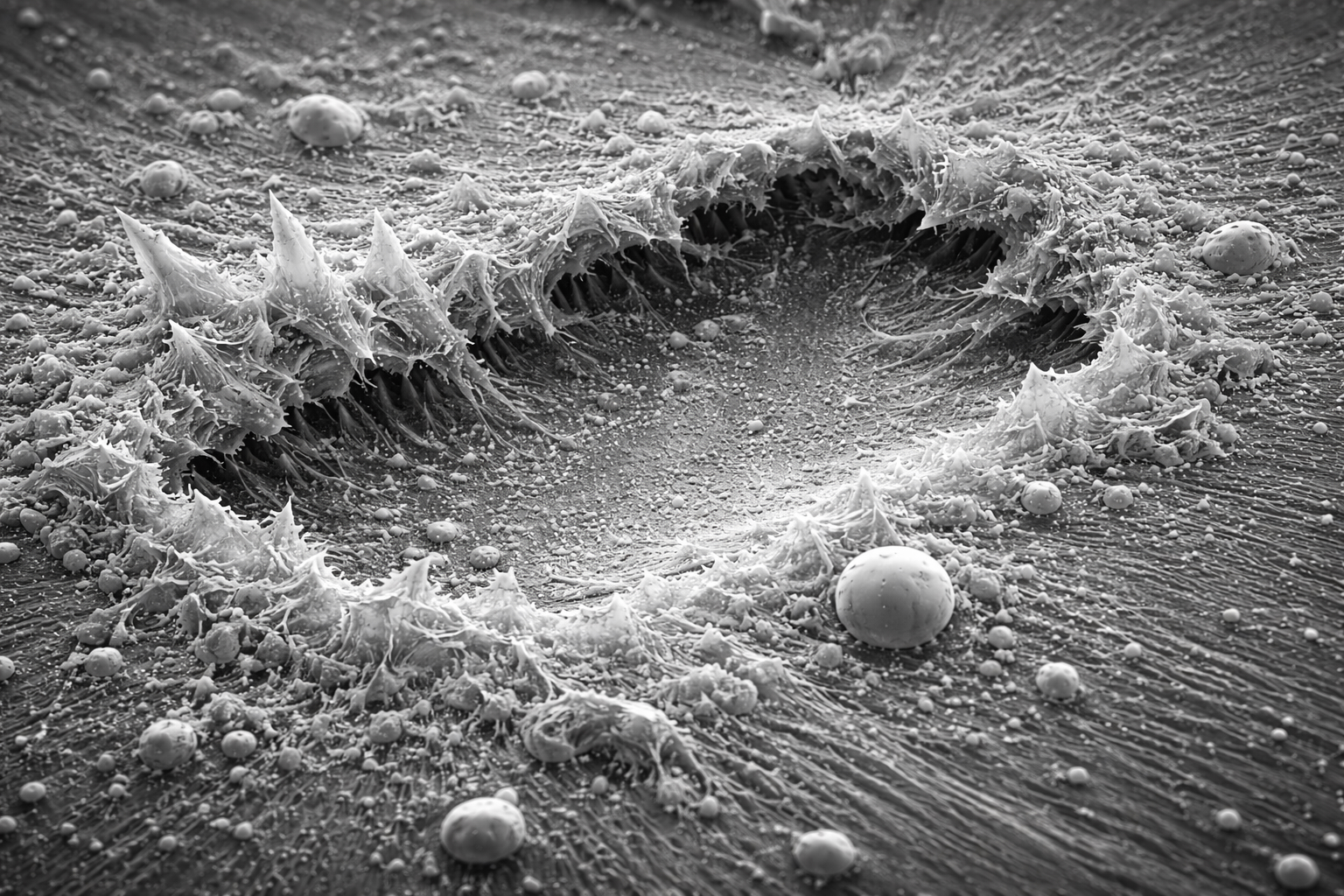

Ultrafast laser surface ablation

Ultrafast laser ablation enables precise material removal from glass surfaces with minimal heat-affected zones.

Due to the extremely short pulse duration, energy is deposited faster than thermal diffusion, resulting in so-called athermal or cold ablation.

This process is commonly used for micro-drilling, cutting and contouring of glass components.

Laser Surface Texturing (LST)

Laser surface texturing (LST) modifies the topography of glass surfaces to tailor functional properties such as wettability, adhesion or optical behavior.

Depending on the laser parameters, micro- and nanoscale surface features can be generated in a controlled manner.

LST is frequently applied in materials research and functional surface engineering.

Laser-Induced Periodic Surface tructures (LIPSS)

Laser-induced periodic surface structures (LIPSS) are self-organized patterns formed on material surfaces under ultrafast laser irradiation.

Their characteristic feature size is typically on the order of the laser wavelength or below.

LIPSS are studied for applications in optics, tribology and surface functionalization.

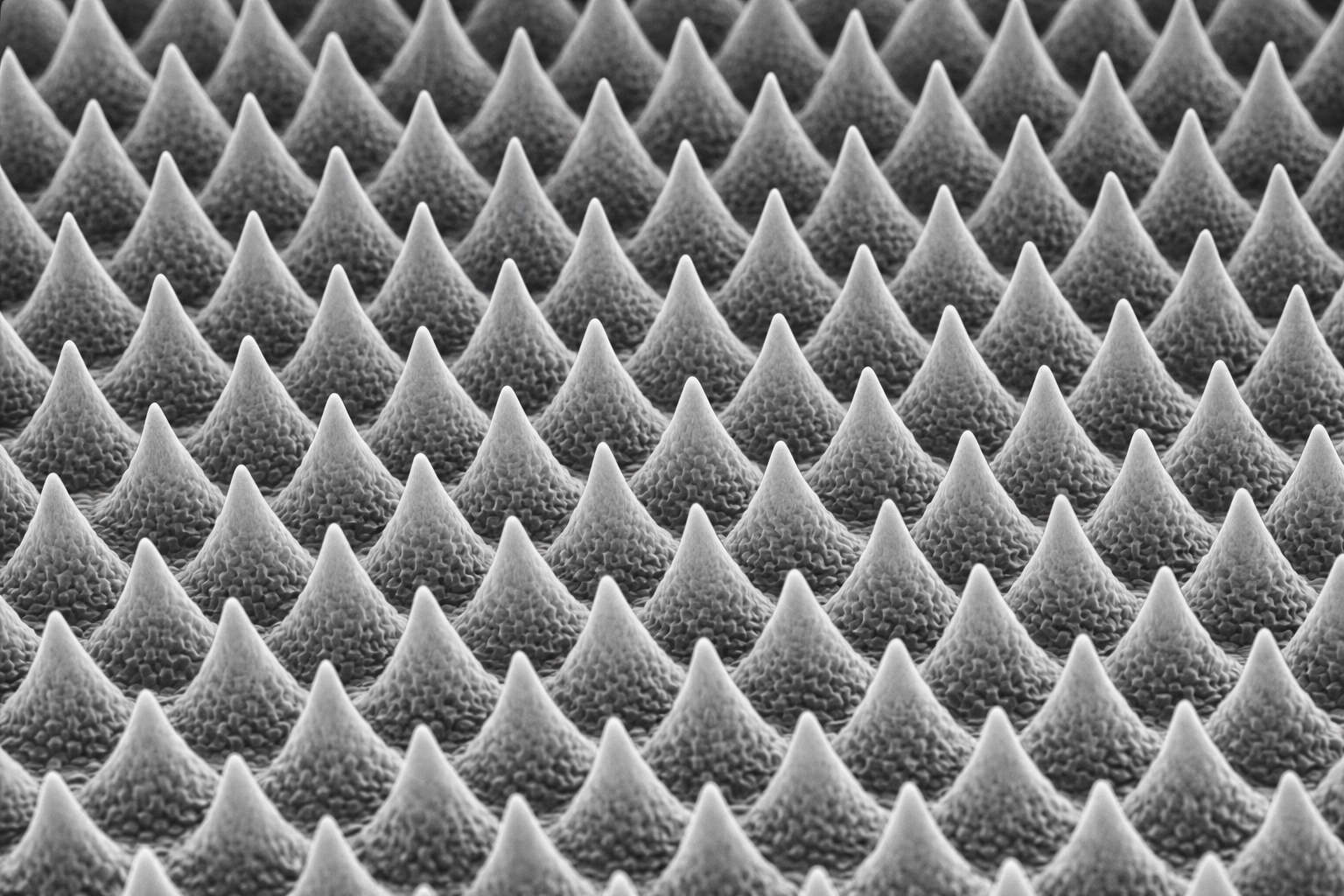

Anti-reflective surface structuring

Laser-fabricated anti-reflective surfaces rely on micro- or nanoscale surface structures that gradually modify the effective refractive index at the glass–air interface.

These subwavelength structures can significantly reduce Fresnel reflections over a broad wavelength range.

Ultrafast laser processing enables maskless fabrication of such structures directly on glass surfaces.

Femtosecond laser welding of glass

Femtosecond laser welding enables direct joining of glass components through localized melting at the interface.

The process allows hermetic, high-strength bonds without adhesives or intermediate layers.

It is particularly relevant for optical assemblies, microfluidic devices and sensor packaging.

Glass–metal and glass–polymer laser joining

Ultrafast laser-based glass–metal and glass–polymer joining enables hybrid integration of dissimilar materials.

Localized energy deposition allows mechanical interlocking or fusion bonding while minimizing thermal stress.

This approach is used in advanced packaging and microsystem integration.

Stress engineering and controlled cleaving

Laser-induced stress engineering allows controlled modification of the internal stress state of glass.

By tailoring laser parameters and scan strategies, predefined fracture paths or controlled cleaving can be achieved.

This is useful for precision cutting and mechanical separation of brittle materials.